Intelligent IoT based major hazard sources and typical operation safety pre-control system

1. Major hazard sources and typical operation safety pre-control system for thermal power plants

■ Key technologies

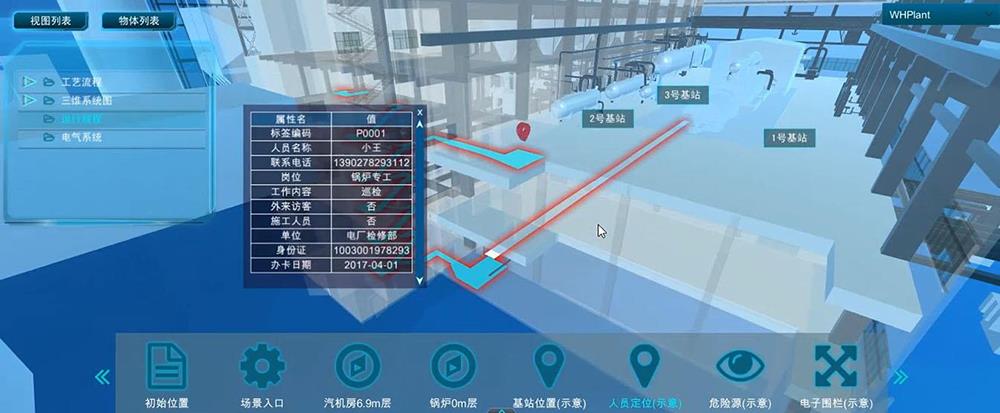

(1) Based on advanced technical means and management tools such as intelligent IoT, intelligent work orders and operation orders, intelligent monitoring, smart wear and smart helmet, to achieve whole process management of safe operation;

(2) Through safety management and control analysis of typical major accidents happened in the power industry for many years, focus safety control on major hazard sources, hazardous chemicals and typical hazardous operations;

(3) In light of the characteristics of electric power production process, convert the abstract safety concept and safety culture into implementable and operable standardized products, to meet the requirements of “intrinsically safe” control.

■ Expected effect

(1) In light of the characteristics of electric power production process, convert the abstract safety concept and safety culture into implementable and operable standardized products, to effectively curb occurrence of accidents having major social impact and personal injuries and casualties;

(2) Enable the Group's branch companies to conduct safety control and effective guidance on major hazard sources, hazardous chemicals and major typical hazardous operations in power plants under their respective jurisdiction;

(3) Enable all power plants to conduct effective monitoring, timely alarm, inspection and supervision during production operation, and perform standardized and systematic management of safety management processes.

Face recognition access control; work clothing & hat recognition; prevention and control of prohibited zones; border prevention; fire identification; illegal overturn warning

Pipeline leakage monitoring; wandering early warning; temporary area management; personnel/work order management system; VIP identification

Ponding early warning; abnormal behavior recognition; vehicle management; key removing identification; human & vehicle positioning...

2. Unmanned inspection and safety pre-control system for wind power system

■ Key technologies

(1) Unified information, work platform, management platform, decision support, and centralized maintenance;

(2) Big data and AI application based expert diagnosis knowledge base and determination of fault location, fault level, fault cause, fault solution and maintenance cost;

(3) Eliminate information silos through horizontal and vertical communication between business and professional data, and realize data sharing and centralized application;

(4) Automatic dimensional evaluation; capable of expanding the function of remote diagnosis service and sharing collective wisdom of experts.

■ Expected effect

(1) The integrated platform forms an innovative management mode, realizes remote unmanned inspection and intelligent control, and effectively controls the operation status of the wind turbine unit;

(2) The technical system formed by the remote diagnosis expert knowledge base helps to establish the data assets of the supervised equipment, improve management of the underlying data, standardize and purify from the basics, carry out all-round and multi-view control, to reduce management costs and accurately control dynamics of abnormal data;

(3) Reduce equipment damage and safety accidents, and effectively prevent major accidents such as tower collapse, serious bearing failure and fire;

(4) Overthrow traditional fault repair, master equipment operation status, make early warning on early failure, realize targeted maintenance, improve quality and efficiency, reduce maintenance cost by more than 30%, to form a new working standard.