From October 2016, we spent three months on implementation of the “Visualized Intelligent Equipment Life-cycle Reliability Management" project in Qingdao Energy Thermal Power Co., Ltd. This project covers:

(1) Diagnosis of the faults and hidden dangers of the equipment through overall inspection and development of a reasonable improvement plan to improve equipment operation standards and regulations;

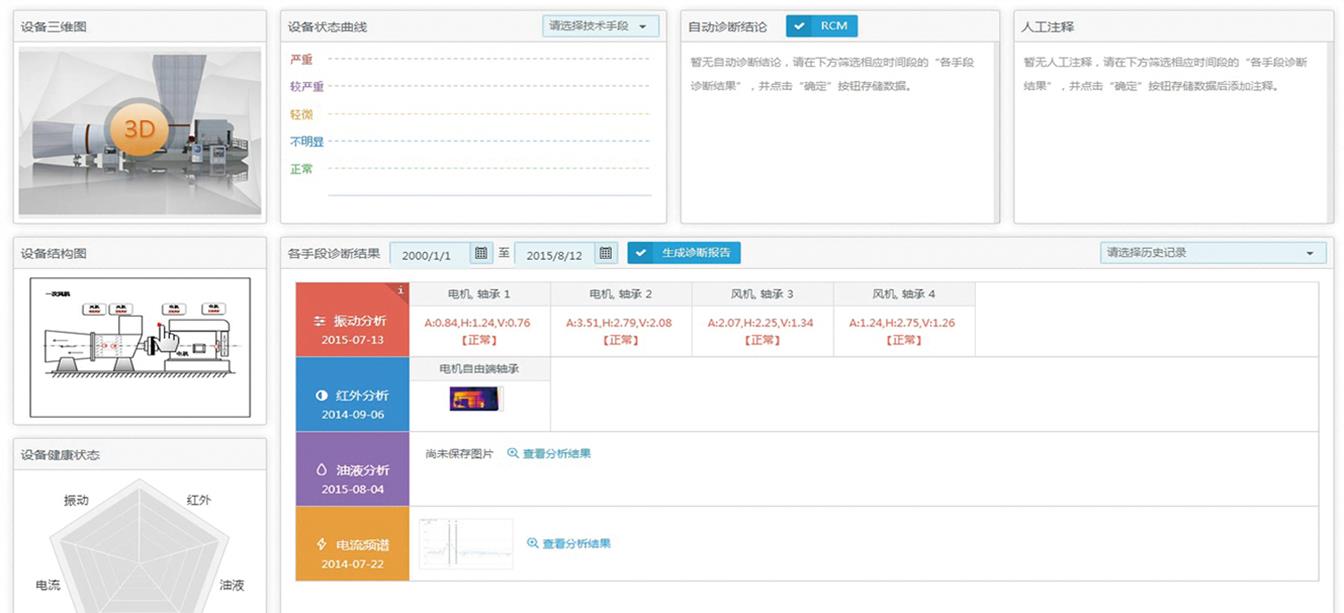

(2) Provision of high-precision, stable, reliable and easy-to-use instruments and equipment, and overall monitoring and analysis of equipment with multiple technical means;

(3) Training on equipment reliability management personnel to masterly operate both software and hardware;

(4) Building of a group-level intelligent life-cycle equipment reliability management system and deployment of a remote platform.

This project enabled unified management of the main equipment and important auxiliary equipment in the power plant and has reduced emergency repair work, avoided abnormal shutdowns, comprehensively raised equipment reliability and safety, and thus greatly lowered the operation and maintenance costs.

This project solved such problems as the dynamic imbalance of the motor and the blade, loosened rotors, broken rotor bars, eccentric stators, misaligned and worn couplers, instable foundation and loosened mechanical connections often found in auxiliary machines in the power plant. It has realized intelligent auxiliary machine comprehensive monitoring and diagnosis of rotary equipment in the power plant, so that the user can learn about the equipment health condition and reliability through real-time monitoring, spectral analysis, automatic fault diagnosis and historic trend analysis on the equipment vibration conditions. The great amount of condition data has greatly improved accuracy of the diagnosis system, raised timeliness of fault diagnosis and will provide accurate and reliable data basis for the future big data platform.