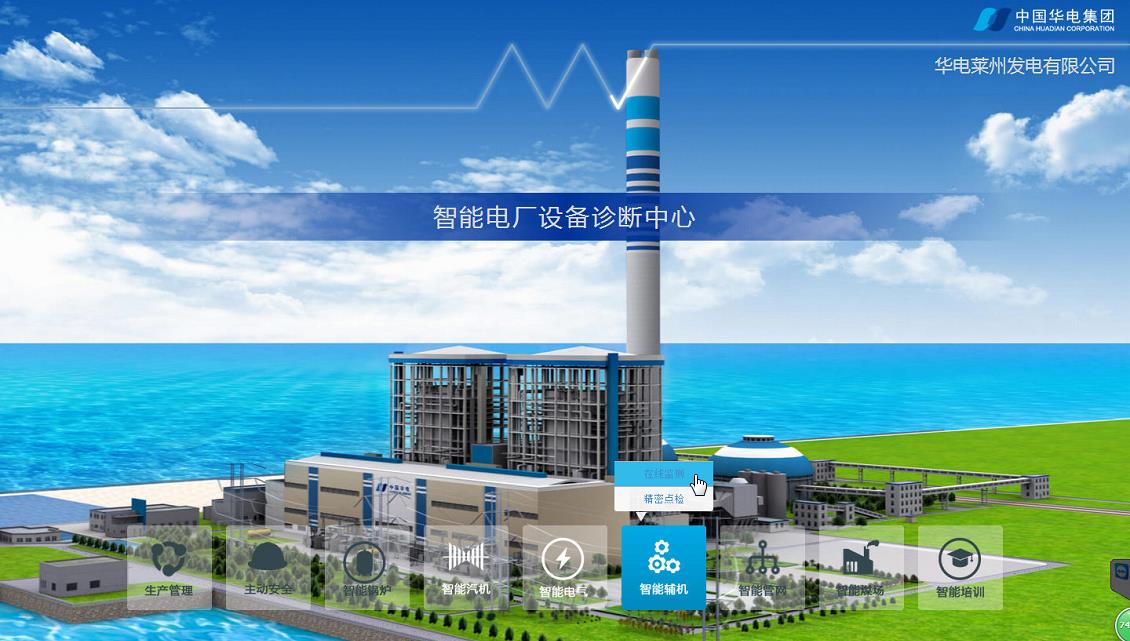

In 2018, we began to implement the “3D Virtual Overhaul Training and Diagnosis Technology Application for Million Units”. This project combines data visualization, 2D+3D integration, video fusion, 3D panorama, VR and AR technologies to build a 3D model to form a maintenance training platform for millions of units.

The system finally realizes the 3D display of the main equipment structure and working principle, so that the user can comprehensively understand the equipment structure and working principle; establishes a realistic virtual interactive 3D space environment, establishes a 3D visualized and intuitive training method, realizes equipment maintenance simulation training, and compensates for the operation simulation then only available in the power plant; carries out virtual inspection training through human interface devices, to comprehensively improve maintenance skills of employees; establishes major equipment maintenance knowledge base and evaluation rules for virtual maintenance evaluation; demonstrates typical equipment faults with the 3D virtual technology and realizes dynamic simulation of the diagnosis results through changing the boundary conditions for verification.

From 2014 to 2017, we successively implemented the visualized large rotating machinery precision diagnosis system, the visualized steam turbine generator unit intelligent safety pre-control system, and the permanent magnet energy-saving retrofit system. On the basis of the original precision inspection system, the later-coming systems realize online real-time monitoring of Class A equipment that directly affects operation of units. With support of massive data, they cannot only support early warning and degradation trend tracking of equipment faults, but also improve the accuracy of system automatic diagnosis.