As the most effective water-saving thermal power generation technology, the air-cooling technology in power plants is widely used in large-scale development of energy and development of power industry in countries and regions where water resources are relatively scarce. With extension of operation time in air-cooling island, many problems will occur, such as: (1) large vibration of fans and steel frames; (2) leakage of fin tubes and uneven change in the temperature field; (3) low efficiency. These problems affect the fatigue of the metal frame of the air-cooling island, seriously threaten the safe operation of the air-cooling island and the normal production of the generator units, reduce efficiency of the generator units, and bring significant economic losses to the power generation enterprise.

BKC has, after multi-year practice and research and development, concluded a complete set of solutions. With the aid of advanced technologies, we have detected and analyzed many problems in air-cooling islands and thereby formed complete and feasible plans. We have established scientific control standards for air-cooling generator units, to lay the foundation for safety production, enable air-cooling unit reliability improvement and life extension, and provide a scientific design basis for air-cooling island manufacturers.

Solution for large vibration of fans and steel frames in air-cooling islands

I. Advanced instruments are applied to conduct comprehensive measurements on motors, fans, and frames in air-cooling islands, to arriving at fault diagnosis results through analyzing measurement data and spectra.

II. The fan motor has insufficient support strength and the coupler type between the motor and the reducer is improper. The multi-dimensional vibration isolation technology is used to eliminate interaction between the gearbox and the motor vibration and eradicate vibration factors.

III. In case of insufficient support strength of the fan motor, the motor bracket with stronger rigidity is designed to enhance the overall structural strength of the air-cooling island and improve the natural frequency of the frame vibration.

IV. Optimization of the reducer: the motor will generate large inertia force under reciprocating vibration, which acts simultaneously with the excitation force of the fan, to increase dynamic load of the reducer bearings and gears. Under the combined influence of design and external factors, faults like broken gears and damaged bearings happen frequently. BKC provides a new set of reducer system according to the specific situation of the equipment, with the safety factor increased by 2.5 times, which can effectively reduce the failure frequency of the reducer and thereby greatly cut the maintenance cost.

Anti-freezing in winter of air-cooling systems is a very important issue in operation of air-cooling units in winter. Freezing in air-cooling tubes is easy to damage air-cooling fin tubes to cause leakage and even worse, endangers safe operation of the steam turbine. Main reasons for icing include: too small steam flow into the air-cooling system to cause too low heat load; uneven air flow. Therefore, it is necessary to monitor the temperature field of the whole air-cooling island and determine partial overcooling caused by uneven air-side flow.

Solution I: wireless transmission temperature online monitor

It is based on the current popular wireless sensor network technology and utilizes the wireless data transmission method to carry out continuous temperature measurement directly on the fin. The indoor model can display the temperature data of multiple wireless temperature detectors, featuring a small temperature probe and easy installation. Both the outdoor collector and temperature probe are designed with enhanced waterproof ability to withstand the harsh external climate and environment.

Option II: install a rotary IR thermal imager on the flusher

This enables to monitor the temperature field of the fins in real time during the flushing process.

Solution for low efficiency of air-cooling islands

1. Regularly clean the air-cooling fins to improve the cleanliness of the air condenser, thereby to significantly reduce the backpressure of the unit.

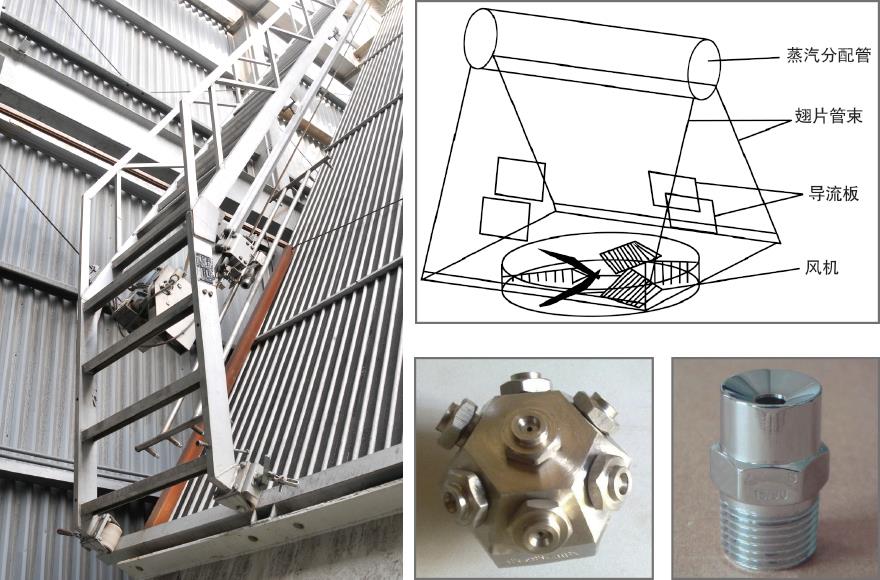

2. Install the guide plate

The air-cooling unit, after being added with the guide plate, has reduced the backpressure of the 330MW unit by 1.1 kPa, the coal consumption rate of the unit by 1.9g / (kW•h), and improved the unit efficiency and output power. The air guide technology is adopted to effectively suppress deterioration of the heat transfer capacity of the air cooling unit in the air-cooling island under the action of the environmental wind field, thereby to improve the ability of the air cooling unit to resist the adverse effects of the environmental wind, decrease the unplanned downtime of the air cooling unit, and improve the unit operation safety and reliability. Compared with the traditional optimized air-cooling condenser, the air-cooling unit reorganizes the flow field through the air guide plate, to improve efficiency of the air volume, thereby to enhance the heat dissipation of the condenser.

3. Spray cooling system

The system consists of the nozzle atomizing device, control device, automatic detection and automatic fault elimination device. In the air-cooling fan room, the spray-enhanced heat exchange system consisting of several nozzles is installed, with the demineralized water spraying fine particles of atomized water droplets around the nozzle at a certain injection angle. The water droplets are in contact with the air at the fan outlet and form a mixture of gas, steam and water through heat and mass transfer. During the evaporation process, water will absorb a large amount of latent heat of vaporization, effectively reducing the temperature of air entering the radiator, while some of the unvaporized water mist will also enhance the heat transfer effect when passing through the heat exchange surface.

Features: high efficiency, reliable work, water saving. The system has applied for a national patent.